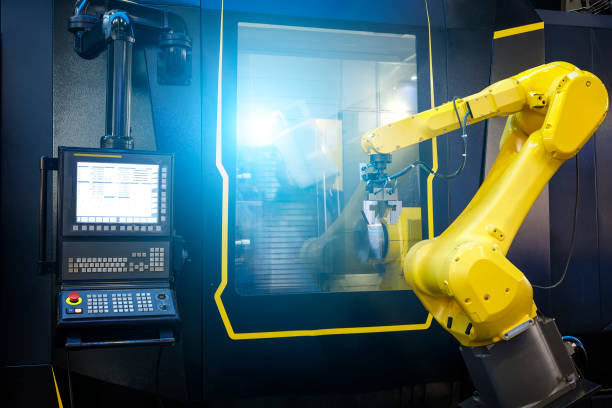

Innovative Solutions Meeting Customer Needs with Automation

High-precision machined components for a large variety of industry applications. For over three decades our extensive experience has resulted in a proven record of achievement, company growth, manufacturing development, customer service and profitability.

Diamond Precision will provide cost effective product through time tested methods of automated manufacturing. Our Manufacturing automation uses advanced technology, including robotics, vision, and specialized software, to optimize production processes. Diamond Precision is leading the way to re-shore products.

Our experiences working with Original Equipment Manufacturers will continue to expand our capabilities thru further automation to meet the highest product standards required in industry.

Precision Machining Services

Through our precision machining services we seek to add real value to our customers’ end products and see ourselves as partners in their success. Our engineering group will develop optimal machining systems to ensure efficient production with consistent results. Along with out precision machining services our value added services and capabilities include: Make-to-order and KanBan scheduling Horizontal and vertical turning and milling State-of-the-art engineering software and measurement equipment Robot automated loading Automatic bar feeders Quick change fixtures Ability to machine parts in excess of 200 pounds Typically, production runs are 250 pieces or more.

Global Sourcing

Importing provides a competitive alternative to domestic production, particularly on small, lower tolerance parts. This service is offered through our Shanghai office. Professional office personnel include purchasing, engineering, machining, and quality control experts.

Balancing & Vibration Control

Customers demand maximum performance and value in today’s global economy. Diamond develops partnerships with our customers to trouble shoot and resolve vibration concerns. Balanced components increase market value, run quieter and last longer. Our engineering group will develop the optimal production systems to ensure efficient, consistent and accurate balancing results. Our balancing minimizes vibration, noise and component wear.